Building a mobile delivery device for Ocado’s fleet of Delivery Drivers

Challenge

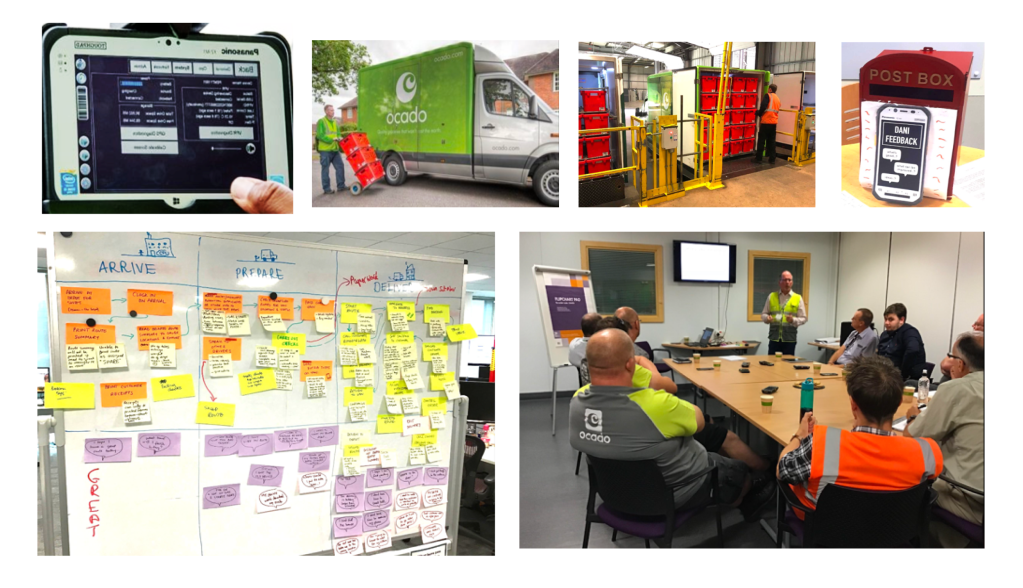

Ocado operates a highly automated grocery delivery service with strict delivery windows and nationwide coverage. While advanced routing algorithms and a large fleet supported the logistics, the tools used by Delivery Drivers were outdated. Drivers relied on a bulky legacy device for inventory management and navigation, paired with printed route summaries. This setup created significant inefficiencies, frequent technical issues, and user frustration—often leading to delays, mistakes, and poor customer experiences.

Project goals

Ocado wanted to build a native Android application to replace the legacy device with modern handheld solution. The application would be built for the Panasonic Toughpad Mobile device. The device had been chosen due to its size, durability and scanning performance in challenging conditions.

Key goals:

- Reduce the number of delayed and missed deliveries attributed to device performance

- Improve safety and legal compliance i.e inventory temperature checks, Challenge 25 processes etc

- Reduce Drivers dependance on print route summaries

Project team

I worked as the sole UX designer working closely with a Product Owner and two Software development teams—one based in England and one in Poland — each comprising of an Engineering Lead, and team Software Engineers. I was responsible for the end-to-end UX including user research, analysis, ideation, prototyping, and design.

Process

Discovery & Research

My first task was to review existing research, user flows, performance data, and an extensive evaluation of the existing device. This enabled me to understand the map task flows, identify knowledge gaps, challenges, points of friction and opportunities for improvements. I then conducted interviews with Site Managers and Drivers at Depots across the UK to understand goals, operational challenges and their experience with the existing device.

To truly understand the day-to-day experience, I joined Delivery Drivers on real shifts, observing their end-to-end journey and taking part in actual deliveries on the route. This allowed me to have a deep understanding of the requirements of the role and the different challenges Drivers face, from downloading their route at the start of the shift to navigating traffic and delivering an order to a customer.

Through my research, it became clear that time was the most valuable commodity for Drivers. Job satisfaction often came simply from finishing their shift early—regardless of how challenging the route had been. If a Driver returned ahead of schedule, frustrations during the shift were usually forgotten.

Because delivery vans must be driven carefully, time savings could only realistically be achieved in a few areas:

- Leaving the depot early – Many Drivers would arrive before their shift started and leave the depot as soon as their route had downloaded. The earlier they could leave the depot, the more chance they had of gaining a time advantage for the day.

- Delivering faster than the estimate – Each delivery had a target time to unload the order and complete the delivery. Drivers would often aim to beat these times (e.g. completing an 8-minute delivery in 5 minutes), gradually shaving minutes from the total route. Beating the estimated return time was considered a personal success and was often the single biggest contributor to job satisfaction.

While Drivers were adept at creating small efficiencies, these gains could easily be cancelled out by external factors such as unexpected traffic. However, I identified areas where the device itself was actively costing Drivers valuable time, adding unnecessary frustration into their daily workflow.

- Device freezing or crashing – During deliveries, the device frequently froze for up to 5 minutes at a time, forcing Drivers to wait until it became responsive again. In the worst cases, the device would stop working entirely, meaning the Driver had to revert to using printed route sheets to complete their round. This not only slowed them down but also resulted in mistakes when manually tracking deliveries.

- Slow download and upload of route data – Before leaving the depot, routes had to be downloaded onto the device, and once the round was completed, the data needed to be uploaded back into the system. Both processes could take anywhere from 15 to 30 minutes and were prone to crashing, often forcing the Driver to restart the entire process. This made it impossible to leave the depot early or finish promptly at the end of the day.

- Manual text entry – Several routine tasks required manual typing where simple selectable options would have sufficed. For example, providing a reason for cancelling an order or processing a refund. This was not only time-consuming but increased the likelihood of inconsistent or inaccurate data entry.

- Manual task flow – Some tasks that occurred regularly but were outside the optimal user journey were not supported by the system. For example, if the container could not be scanned the Driver had to manually identify the order by cross-referencing the printed order summary with the physical items, a process that added significant time to what should have been a quick step.

- Driver notes not up to date – For difficult or unusual delivery locations, Drivers often relied on notes left by colleagues who had delivered there before. These notes contained valuable guidance, such as parking instructions, gate codes, or warnings (e.g. “Customer has large guard dogs on the property”). These notes, were buried deep in the interface, making them hard to view, add or update. Drivers didn’t trust the information as they were unsure if it was reliable and wasted time navigating difficult stops.

Opportunity mapping & Ideation

I ran workshops with the different Product teams to explore opportunities and solutions to potential technical challenges and usability issues. I shared the insights gathered, and we collaborated to map workflows, user challenges, and opportunity areas. We understood that reliability, speed and accuracy were above everything else were the most important factors. If we built a reliable, robust service then planned workflow changes and device adoption path would be much easier.

Prototyping & Testing

Based on user insights and collaboration with Product teams, I built wireframes and developed a prototype I could take to depots across the UK and validate task flows, ideas and feedback on the new device that would be introduced. It was difficult to get detailed user feedback as Drivers were mainly concerned with reliability of the service and prototype was only demonstrating workflow improvements and a new shiny device. however, the feedback was encouraging and demonstrated we were on the right path – but it was clear we need to introduce a product into the field a quickly as possible to gain real insights.

Beta product release

I worked with the teams of Developers to build a beta version of the app with that contained the key task flows and features. We deployed the device at a single depot to allow targeted feedback. Over the course of 2 weeks, each day a selection of Drivers were chosen to take the new device out on their route and use as their primary delivery. To gather feedback we would conducted interviews with Drivers before going out on their route and also when they returned. We would ask consistent questions regarding the experience and would get Drivers to rate the experience and compare this to their experience using the existing device. After this period, all known bugs had been ironed out and all Drivers in the depot were then given the new device to use during their shift. The results overall were very encouraging as the new device was consistently being rated as a much better experience with drivers commenting that they would want to use the new device over the older device.

The key area that in which we received positive feedback

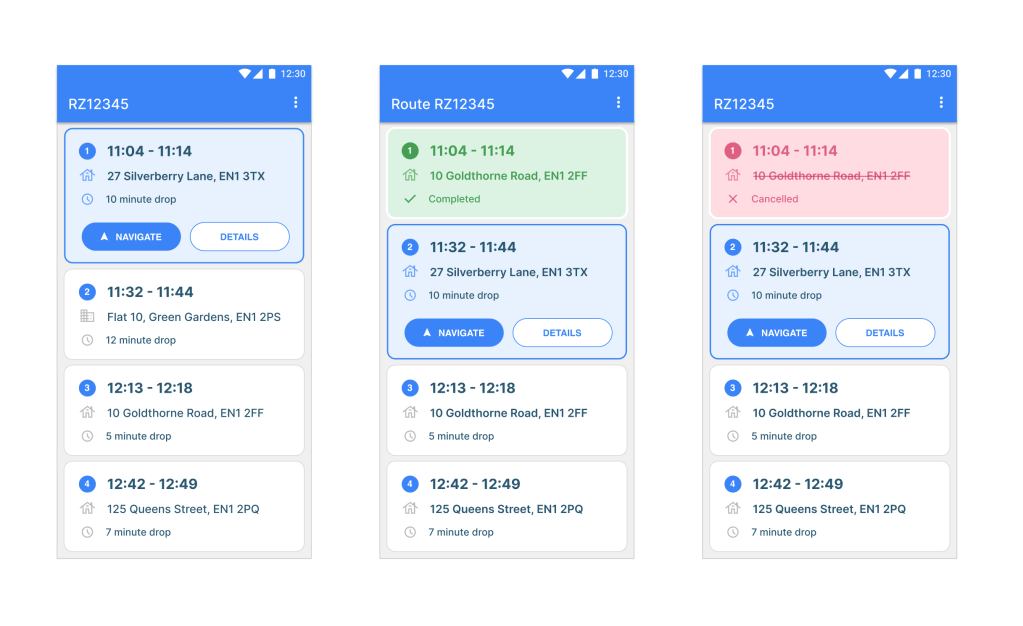

- Integrated route information: The new app provided all the key drop information up front to the Driver which meant that the printed route summary was not needed unless there was a technical issue. Drivers commented on improved efficiency and simplicity of viewing and editing the Delivery notes. The accuracy and usefulness of the notes were also improved as more Drivers updated the information.

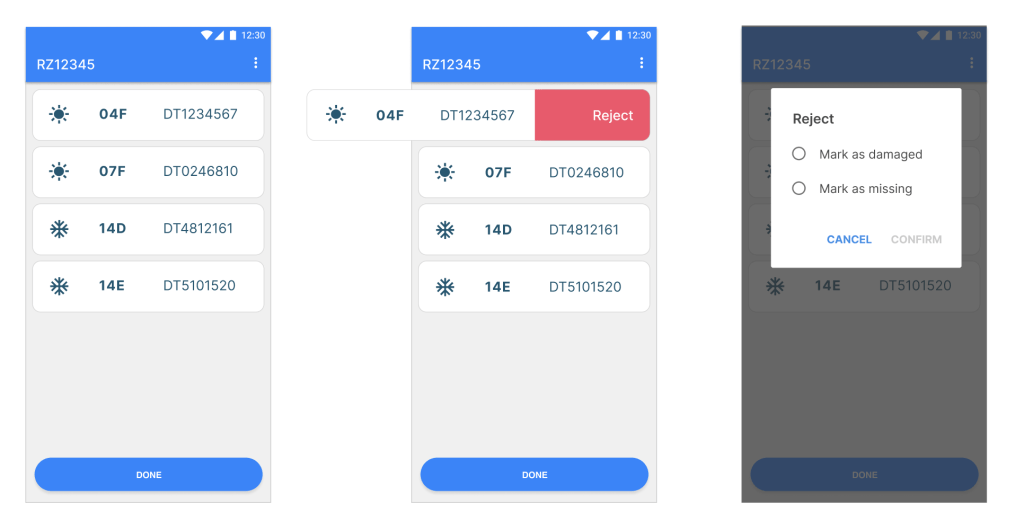

- User friendly workflows: Processes were simplified wherever possible, with clear iconography for quick recognition and common gestures (e.g. swipe to delete) for key actions. Manual text entry was replaced with selectable lists to reduce friction. Additional features were provided to help Drivers quickly identify missing or unknown totes and send SMS messages to customers when running late – saving valuable time during deliveries.

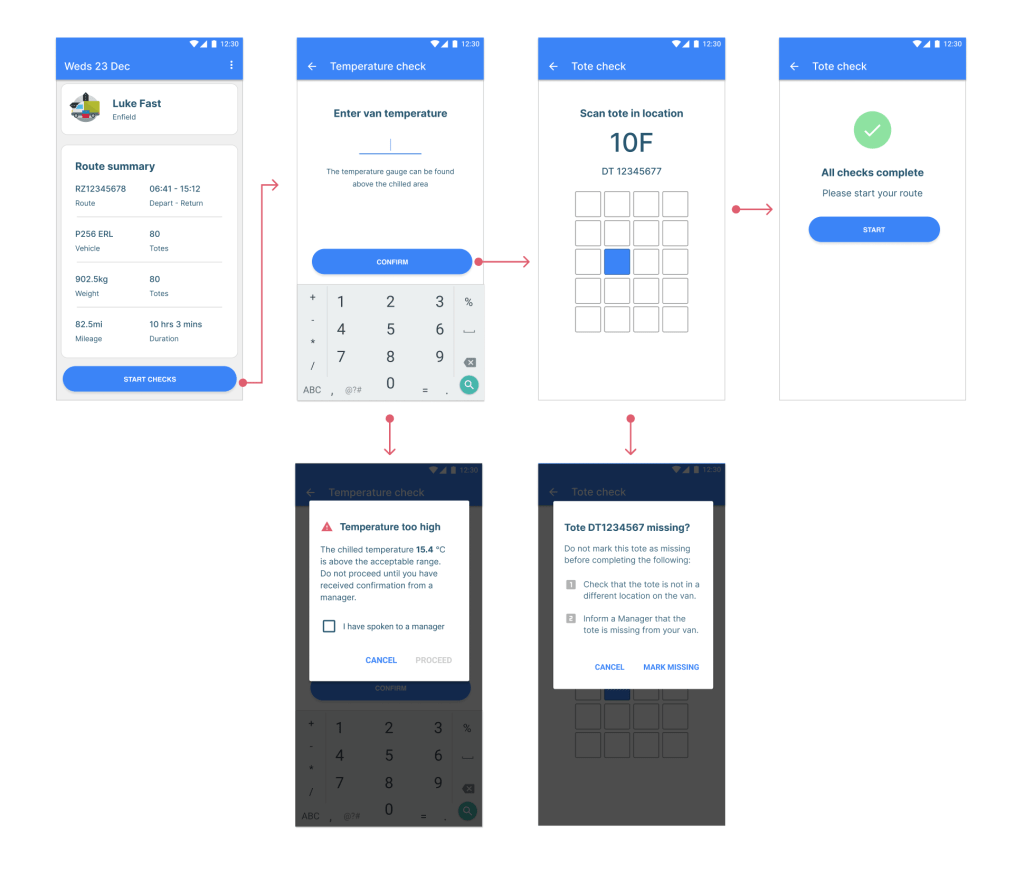

- Improved vehicle and safety checks: The new app introduced detailed inventory verification and required Drivers to manually enter van temperature readings to adhere to food safety protocols and also scanning some barcodes to ensure the correct inventory had been loaded onto the van. Site Managers praised this feature as it ensured Drivers were going through the correct protocols. Drivers were initially hesitant about the additional mandatory steps, but many later expressed appreciation for the added protection it offered. If a van overheated during a route, Drivers could now demonstrate they had followed procedure before departure.

- Improved performance: Performance was a improved significantly with the new device boasting a 98% uptime compared to the previous device at 75%. The upload/download times were also reduced from an average of 16mins to just 4 minutes, significantly speeding up shift preparation and reducing depot congestion during busy periods.

There key areas in which we received negative feedback:

- Scan sounds unclear in noisy environments: Some Drivers reported that the audio feedback for successful vs unsuccessful scans was too similar—particularly when working near busy roads or noisy environments. This meant they had to keep their eyes on the screen, slowing down the unloading process. We curated a new set of scanning sounds that were longer, more distinct, and easily distinguishable. These were tested both in depot and at roadside locations to ensure they performed well under real-world conditions. The updated sounds improved confidence in the scanning process and reduced task completion time.

- Text readability for older Drivers: Several Drivers over the age of 55 reported difficulty reading smaller text on the new, smaller screen compared to the older device. We introduced a text size adjustment feature in the app settings, allowing users to choose a larger font size for improved readability. This small but critical change helped improve accessibility and reduced cognitive load for older users.

Service wide release

Following the successful trial at a single depot, the new device was gradually rolled out across additional sites. Throughout this phased launch, we continued to test and iterate—adding new features, addressing technical challenges, and implementing ongoing user feedback. The final application was successfully deployed to all depots across the UK, where it was well received by both Delivery Drivers and Site Managers.

Outcome

The project successfully met its goals, delivering significant business savings and improved driver satisfaction:

- £2 million estimated annual savings from fewer failed or delayed deliveries, reduced hardware maintenance, and lower printing costs

- Higher operational compliance through integrated legal and safety workflows

- Improved driver satisfaction, thanks to better performance, reliability, accessibility, and overall UX